Umkhiqizo

Inqwaba yensimbi engagqwali i-fibre noma i-textile inner core conductive wire yezindwangu ezifudumalayo

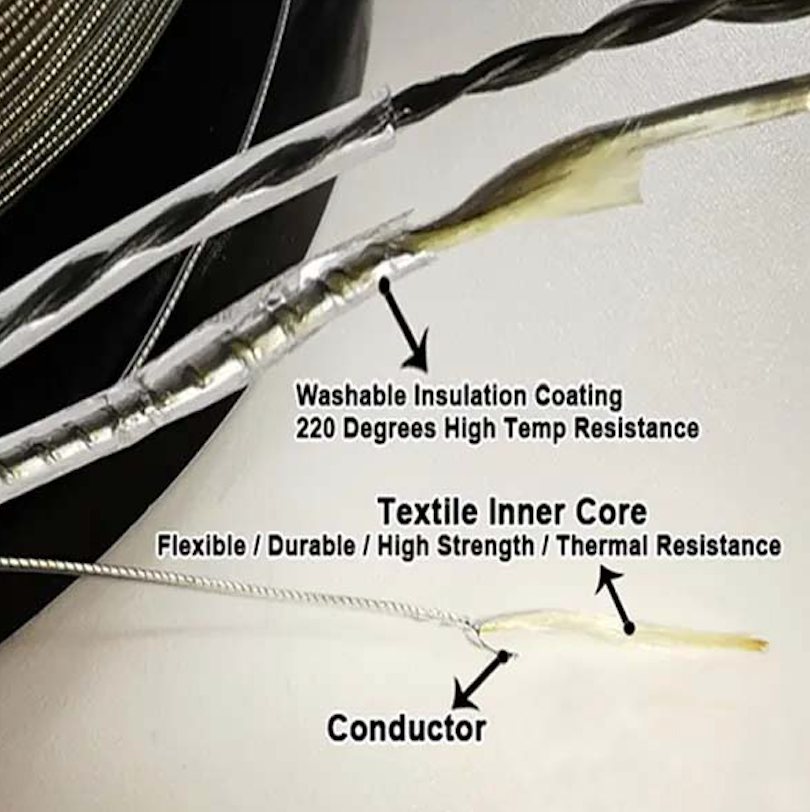

Incazelo Yomkhiqizo

1-Inqwaba esekelwe ku-fiber yensimbi engagqwali lapho ububanzi befayibha ngayinye ingu-12µ noma 14µ. Inani lemicu ngokuvamile lisukela kuma-200 kuye kwangaphezu kuka-1500. Lokhu kukunikeza ukuqina 'okuhamba phambili ekilasini'. Ngenxa yemicu emihle esetshenzisiwe, lezi zintambo zisalokhu zizacile ngobubanzi bawo wonke futhi ngaleyo ndlela ziguquguquka kakhulu lapho zicutshungulwa.

2-Simboza ububanzi obubanzi bokumelana okuphansi kwentambo ecwebezelayo eyengeziwe kanye nezintambo ezincane ezinezici ezihlala isikhathi eside neziguquguqukayo, ikakhulukazi zethu ngezintambo ezincane ezingaphakathi zendwangu zingakwazi ukumelana nemitha ngayinye oyidingayo futhi zikunikeza ukuguquguquka okwengeziwe ekwakhiweni kodwa zisakunikeza okungcono. ukuphila okuguquguqukayo kunamakhebula e-Cu ajwayelekile. Kuya nge-alloy egoqwe yangaphandle engenziwa ukuthayela, ithusi, ingxubevange yesiliva njll, singakwazi ukukhiqiza izintambo ezincane ezikwazi ukumelana ne-1 ohm/m ngezinhlobo ezingashadile nezixhunywe ngokuvumelana nemfuneko yamakhasimende.

Izinzuzo zezintambo ezincane ze-textile zangaphakathi

Ukugoba Ukumelana

Ngenxa yesakhiwo nokuhlanganiswa kwezinto, ucingo lunokumelana okuhle kakhulu kokugoba.

Ukuvumelana nezimo

Izintambo ezincane zisebenzisa i-foil yensimbi emincane kakhulu njengomqhubi, ebona ukuguquguquka okukhulu.

I-Ultra-Fine

Ngemuva kokukhipha ikhebula elincane lethu elincane kakhulu lingaba ngu-0.35mm.

Amandla Okuqina Okuphakeme

Sisebenzisa imicu ye-Aramid / Liquid Crystal Polymer kanye nemicu ye-self engineer high tech.

I-High Temp. Ukumelana

Sisebenzisa i-aramid noma i-stanless steel fiber bundle filaments kumafayibha, ukumelana nokushisa okuphezulu kusuka ku-230 degrees kuya ku-580 degrees ngokukhetha kwakho.

Ukuqeda & ukunamathela

Emhlabeni wakho, kunesidingo esikhulu sokuhlanganisa imicu ngakunye noma i-extrusion coating phezu kwekhebula eliphelele. Singakwenza futhi lokho,okuqukethwe kwethu kwe-extrusion kufaka i-FEP,PFA,PTFE,TPU njll.

INCAZELO YEJAcket LOKUGQIBELA

| I-Extrusion | I-TPE | FEP | I-MFA |

| Melting Point | 205° C | 255°C | 250°C |

| Cokuqhubekayo Ukusebenza Tumkhathi | 165°C | 205° C | 225°C |

I-Stainless Steel Fiber Bundles

Textile Inner Core Micro Cable Constructions

Esekelwe Embroided Heating Element

Insimbi engagqwali ihlanganisa imikhakha ehlukene yokumelana nereferensi yakho.

| Ububanzi (um) | Imicu | Amandla (cN) | Isisindo (g/m) | Ubude (%) | I-Conductivity (Ohm/ m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

I-Textile core conductive wire ububanzi obuhlukene bokumelana

| I-Outer Conductor | I-Textile Inner Core | Ububanzi mm | I-Conductivity ≤Ω/m |

| Ithusi 0.08mm | I-Poyester engu-250D | 0.20±0.02 | 6.50 |

| Ithusi 0.10mm | I-250D Polyester | 0.23±0.02 | 3.90 |

| Ithusi 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Ithusi 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Ithusi 0.1mm | I-250D Polyester | 1*2/0.28 | 2.00 |

| Ithusi 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Ithusi 0.05mm | I-50D Polyester | 1*2/0.13 | 8.50 |

| Ithusi 0.05mm | I-70D Polyester | 0.11±0.02 | 12.50 |

| Ithusi 0.55mm | I-70D Polyester | 0.12±0.02 | 12.30 |

| Ithusi 0.10mm | Ukotini 42S/2 | 0.27±0.03 | 4.20 |

| Ithusi 0.09mm | I-150D Polyester | 0.19±0.02 | 5.50 |

| Ithusi 0.06mm | I-150D Polyester | 0.19±0.02 | 12.50 |

| I-Tin Copper 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| I-Tin Copper 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| I-Tin Copper 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| I-Tin Copper 0.10mm | I-250D Polyester | 0.23±0.02 | 4.00 |

| I-Tin Copper 0.06mm | I-150D Polyester | 0.16±0.02 | 11.6 |

| I-Tin Copper 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| I-Tin Copper 0.085mm | I-150D Polyester | 0.19±0.02 | 6.00 |

| I-Silver Copper 0.10mm | I-250D Polyester | 0.23±0.02 | 3.90 |